Terminology

In the manufacture of hinges, particularly special or “specialty” hinges, a variety of terms are used to describe and dimension the required hinge structure. These terms are not generally understood and therefore, will attempt to describe different terms and where necessary illustrate them. As there is no standard of hinge terms that has been accepted by the entire industry, we will present those that are in current use.

How to Specify

When requesting prices and/or ordering special hinges, as much complete dimensional information is necessary for us to accurately respond to your request. We’ve provided an illustration to indicate the various dimensions we will require as well as a guide to materials, sizes, types and features of the finished hinge.

A. QUANTITY

We will fill an order for any quantity, whether for pilot or production runs. Price based on quantity required.

B. GAUGES (Thickness)

Steel to .500

Stainless to .375

Aluminum to .250

Brass to .250

Titanium to .187

C. WIDTH

Usually expressed in terms of when the hinge is fully open, with widths available up to 32" for each leaf.

D. UNEQUAL LEAVES

Leaves of unequal length or width are measured from the center of the barrel of the hinge curl.

E. LENGTH

Generally up to 120". In some gauges up to 18'.

F. TYPE OF LEAF MATERIAL

Steel: Soft, quarter hard, half hard. Cold and hot rolled grades. (Pickled and oiled)

Stainless: Types 302, 304, 316, 321, 430 in 2B finish. Other types and finishes available to order

Aluminum: Soft, quarter hard, half hard. 5052 and available in 3003

Brass: Soft, quarter hard, half hard.

Note: Unless otherwise specified, hinge material will be furnished as follows:

Steel: CRS or HRPO in 1010 series (mild)

Stainless: Commercial

Aluminum: Half hard

Other materials such as zinc, copper, bronze, titanium, etc. are available providing materials are sufficiently ductile to allow forming of the hinge curl.

Certification of Compliance and/or Material Test Reports are available

G. DIAMETER OF PIN

.035 to 1-1/2 dia. in all solid round gauge ranges.

H. TYPE OF PIN MATERIAL

Steel, Stainless, Aluminum, Brass and Nylon. Tubing also available.

Steel: Wire or bar (depending on gauge) 1010 - 1020

Stainless: Types 303, 304, 316, 416

Aluminum alloy; Tempered 2017-T4

Brass: Half hard

I. TYPE OF ASSEMBLY

Various methods of pin retention available including: flush, spun, loose, brazed or welded, swaged, formed, tapered drive pin, etc.

J. SIZE OF HOLES

Typically, stock hinges are manufactured without holes; the application of the product being made by spot or tack welding or drilling holes at assembly. Standard hole punches include:

Square: .172 - .437

Oblong: .140 x .187 - .750 x 1.000

Round: .098 - 1.375 dia

Rectangular: .218 x .875 - .375 x .750

Holes may be punched in material of gauges up to .375 thick, within tooling limitations. Other configurations available.

K. HOLE LOCATIONS

Standard hole centers, straight-line or staggered, are 2", 3", 4", 5" and 6". Other spacings available at extra charge.

L. COUNTERSUNK HOLES

If a screw or rivet needs to be countersunk please specify: cut, depressed or embossed

M. FINISHES

Standard hinges are provided unfinished unless specified, but there are unlimited plating and polishing finishes available and only limited to design, size and end use.

N. SWAGGING/OFFSETTING

Various forms of altering the hinge leaves to meet the needs of the application are available.

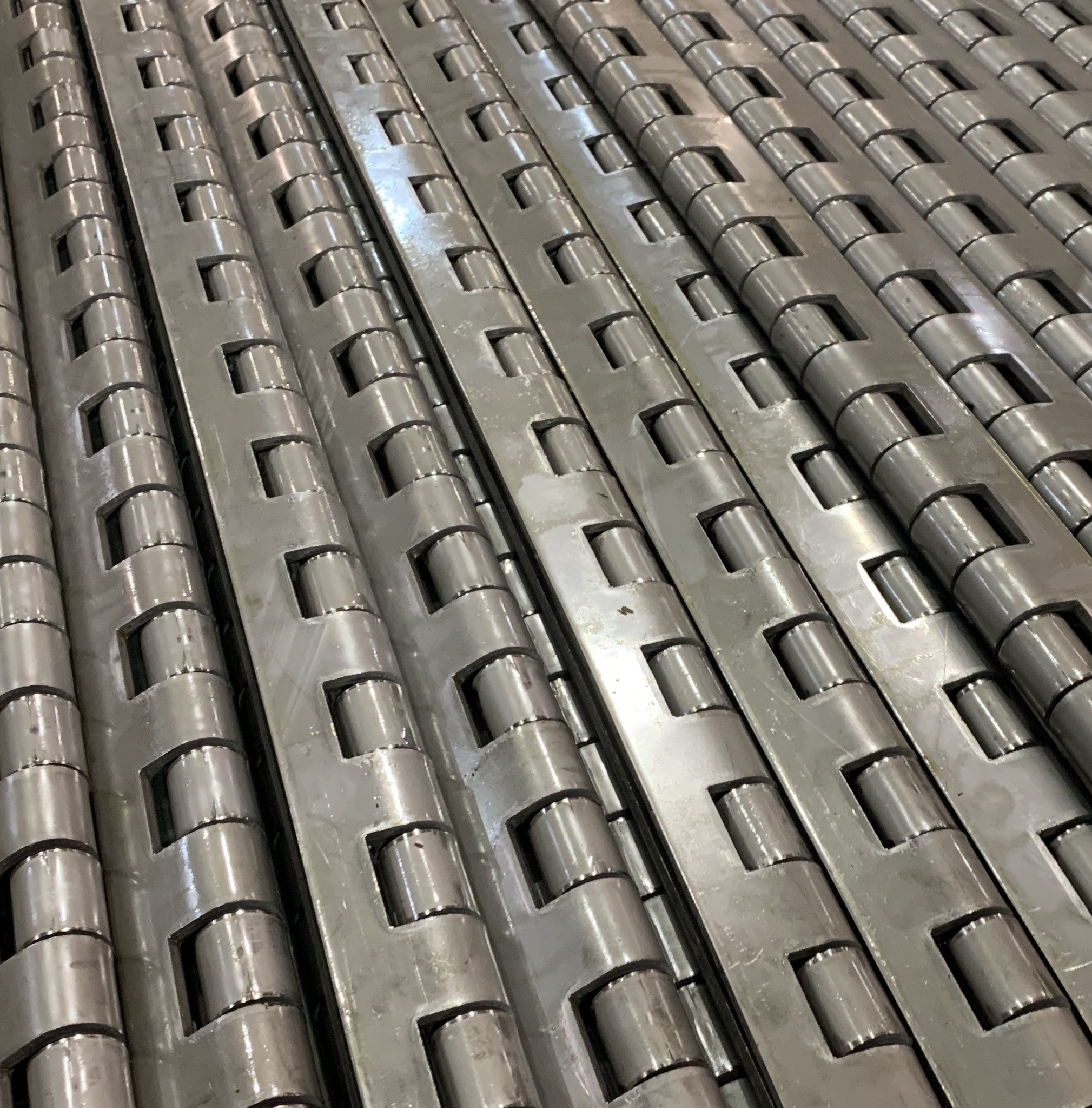

O. JOINT OR KNUCKLE LENGTH

Also referred to as knuckle, loop, node or curl, denotes the part of the hinge which forms the sections through which a pin passes. This and the notch make up the hinge length. Usually the joints in lighter gauge hinges are of shorter length.

P. PAINT CLEARANCE

Hinges manufactured for industrial applications are generally provided with allowances for paint or plating clearance at the width of the joint and depth of the notch.

Q. HINGE ASSEMBLY

Unless otherwise indicated, a surface type hinge will be provided.

R. NOTCHING OR TRIMMING

The notching or trimming of one or both ends of a hinge are available where application is necessary.

S. WELD NUTS OR STUDS

Are available when greater holding power is needed.

T. HOLE TAPPING

We are equipped to tap holes in any type of material provided that the gauge thickness will allow for at least two (2) threads. Hole extrusion for a greater number of threads is also available.

U. FILLET WELDING OF KNUCKLES

The fillet welding of hinge knuckles is applied to hinges which are normally mounted horizontally and in service subject to severe pressures, such as tailgates on dump trucks, and where considerable weight pulls from the pin. Fillet welding of a few knuckles on each end is usually sufficient and greatly increase the yield strength of the hinge.